Section WFP 2-01 – Welding Fabrication Procedure Rev. 1, 10/27/06 Attachment 4, ASME B31.9, Building Services Acceptance Criteria 1.0 ACCEPTANCE CRITERIA FOR COMPLETED WELDS 1.1 Butt Welds 1.1.1 No cracks are permitted 1.1.2 As-welded surfaces are permitted; however, the surface of welds shall be.

Launch Disk Utility (in /Applications/Utilities) and then drag BaseSystem.dmg (in the OS X Install ESD volume) into Disk Utility's left-hand sidebar. Select BaseSystem.dmg in Disk Utility's. How to Burn DMG to USB on Mac for Free (Disk Utility) The native disk image utility on Mac is ideal. You must know the system requirementsof OS X Yosemite before installing it, If your system to capable to run this OS X version 10.10 then Shutdown your Mac, plug the OS X Yosemite Bootable USB into Mac. Press the power button again to turn it On and then hold the Alt or Option key from keyboard, when you see this screen release the button. Os x yosemite dmg to usb.

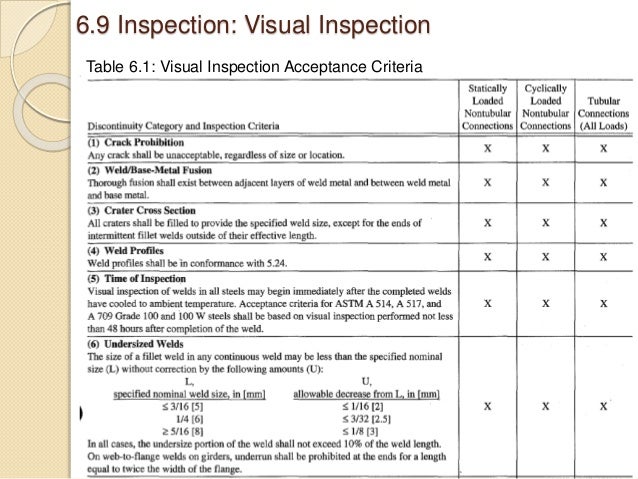

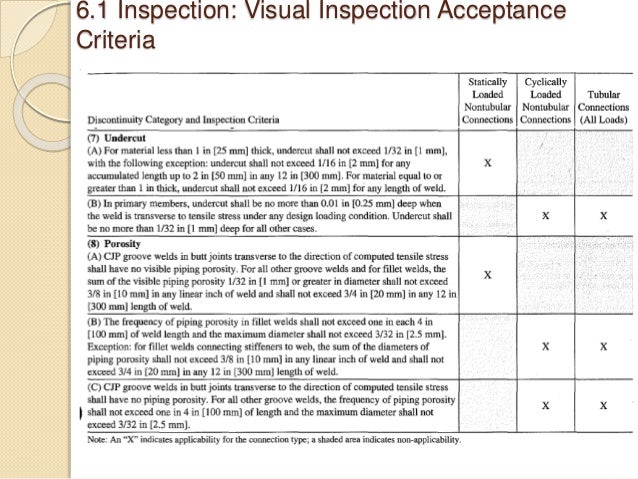

As stated previously, radiographic testing may be used in lieu of bend tests. Procedures, technique and acceptance criteria for this type of test is provided in Clause 8 (Inspection) of AWS D1.1/D1.1M:2020 Structural Welding Code – Steel (Clause 6 if you are still using the 2015 edition). To more explanation about Visual Inspection Acceptance Criteria you can open AWS D1.1 section 6 (inspection) part C. Before you inspect and make decision about weld as per AWS D1.1, you must know definitions of: 1. Statically Loaded Nontubular Connections (more detail see Section 2 part B AWS D1.1). Video about welding inspection education It covers topics below welding defects covered in AWS D1.1 acceptance criteria for the welding defects porosity this. The acceptance of performance qualification to alternate codes or standards is recognized by AWS D1.1 in the qualification clause, but requires approval of the Engineer. Gtaw (Structural) 4 Jan 18 20:43 The acceptance criteria of ASME is not as stringent as AWS D1.1. Blackweb keyboard color changer download.

Aws D1.1 Weld Acceptance Criteria

Aws D1.1 Weld Acceptance Criteria

Aws D1.1 Table 6.1

Aws Visual Inspection Report Form

by online welding courses – non destructive testing